| Products List | ||

| Online Service | ||

|

||

|

||

|

||

| Social Network Site | ||

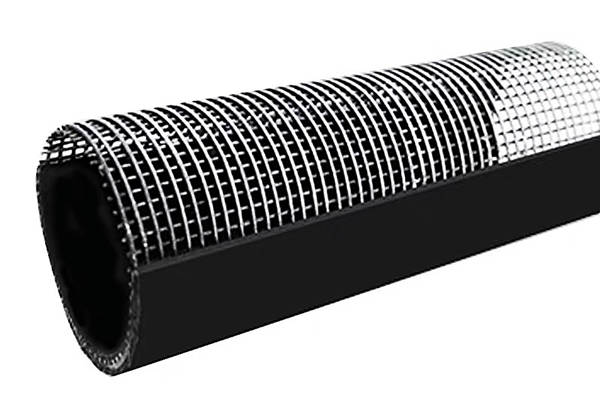

| What are the factors that affect the production quality of steel skeleton PE composite pipe? |

|

In the production process of steel skeleton PE composite pipe, some factors will affect the production quality of the pipe. The rust treatment method of PE steel skeleton composite pipe specifically includes the following points; 1. Selection of pipe materials There are many kinds of standard trademarks of pipes, countless, and the raw materials of the same trademark can produce pipes but cannot produce PE pipes. Here it is still necessary for the manufacturer to identify by himself, select the appropriate pipe material, and check the performance of the material more when selecting.

2. Unstable temperature When processing hard steel skeleton PE composite pipe, because the processing temperature is relatively close to the decomposition temperature, the material temperature at each point should be strictly controlled during production. If the temperature is too low, the plasticization is not good, and if the temperature is too high, the material is easy to decompose. The temperature control should be Judgment based on the original formula, extruder and head structure, screw speed and other factors, while paying attention to the error of the temperature measurement surface and the location of the measurement point. 3. Selection of screw speed The screw speed depends not only on the size of the extruder, but also on the size of the upper pipe diameter. The increase in the speed and the increase in the extrusion volume will increase the shear force on the material, which is conducive to the plasticization of the material, but the residence time of the material in the screw Shorter, too high friction heat makes the inner wall of the tube rougher and the strength of the tube is reduced. Therefore, the control of the screw speed should be fully balanced according to the output, product appearance and physical and mechanical functions.

|